Engine swap and restoration#

Body work and full respray#

In April 2022, the time came to start disassembling the original Golf engine and prepare the car for the body work and full respray.

In general terms the car was in very good condition, it only had a little rust on the right front wing, the rest was impeccable. And the body shop confirmed it once the panels were removed to start preparing them for respray.

In this case, and following the advice of the body shop, a full restoration of the body including; exterior, engine bay, interior of the doors, wheel arches and plastic moldings was done with a very good results.

The final result is 2 months of work by the body shop and the left and right front side wings changed as the old ones were rusty (quite common in this type of Golf). In addition, some lateral plastic trimming was also changed as it was broken.

At the end of June 2022 the car is back in the workshop with Marc, and it’s time to start messing with the mechanical parts.

Front and rear axles#

Front axle#

As previously mentioned, in order to be able to make the engine swap road legal, the size of the front discs and the number of caliper pistons must be at least the same as the donor vehicle.

In the case of the Golf MK5 GTI, the discs are 312x25mm with a single-piston caliper. After countless hours browsing internet to find the perfect BBK (Big Break Kit), that is, good, nice and cheap, I decided to go for a CEIKA kit; 345x32mm and 6-piston calipers, a monster!!. But I was wrong twice.

From the beginning I was wondering if I had 17" or 18" wheels, after thinking about it a lot I decided on 17" BBS wheels. At the time of buying the BBK, I had not yet chosen the size of the wheels, so I bought a disc size that was as big as possible and could be mounted on 17" or 18" rims. And I chose 345mm, but these discs fit very tightly on a 17" rim. In fact because of the profile of the 17" rim those discs were rubbing against the rim.

In short, the disks were too big. Therefore, I thought of using the 334x32mm discs from a Golf MK4 R32 with the CEIKA BBK calipers. But for this setup I had to design some custom adapters that Epytec made.

My second big mistake was buying the BBK from CEIKA. Their customer service is terrible, and I certainly would not recommend CEIKA to anyone. Today, if I had to buy a BBK for a Golf MK3 I would do it through Epytec; Golf MK4 R32 discs (334x32mm) and ZR17 calipers from Porsche Cayenne or VW Tuareg.

To complete the configuration of the front axle, the following elements were added:

- New coilovers.

- Epytec drive shafts. It is important to note here that these shafts are compatible with 02Q gearboxes placed in the OEM position, and the kit from Fabless Manufacturing leaves the motor and gearbox in the OEM position, so everything fits 😅.

- New sway bar to replace the existing one.

Rear axle#

Luckily, I didn’t buy the BBK for the rear axle from CEIKA 😅. I have to admit that I was tempted, but in the end, after looking for alternatives, I discovered that my friends at Epytec have a kit that is perfect and much cheaper.

- 310x22mm discs from the VW Phaeton.

- Golf MK4 R32 rear calipers

- Epytec adapter for calipers/discs.

In summary, except for the adapter, standard parts that can be found in multiple online stores.

As a bonus, a sway bar has also been added to the rear axle 😀.

Engine rebuild#

ETKA and the various vehicles used for the swap#

Before starting this project, September 2021, I knew very little about mechanics, now I can say that I still don’t know about mechanics, but I have become, after many hours, an expert in searching in ETKA of the VAG group the pieces that are needed 😇.

Any swap involves finding and assembling parts from more than one vehicle. In this specific case, parts of the following vehicles have been searched for and purchased:

- Golf MK3 GTI. This is the receiving vehicle, so the parts that have been purchased for this vehicle are mostly bodywork, interior and aesthetics (emblems and anagrams).

- Golf MK5 GTI. This is the donor vehicle. Most of the engine parts belong to this vehicle.

- Golf MK4 R32. References to this vehicle are the front brake discs and the rear brake calipers. Both need custom-made adapters to be able to be mounted on the Golf MK3.

Engine purchase and rebuild#

As for the engine and gearbox, I got these from a scrapyard in September 2021. Be careful when you buy the engine that it is a BWA and not a BWE. Both engine blocks are identical, but one is mounted transversely and the other longitudinally. A BWE can be mounted transversely (certain parts have to be changed), but the problem is that it can never be made road legal as it is not mounted longitudinally.

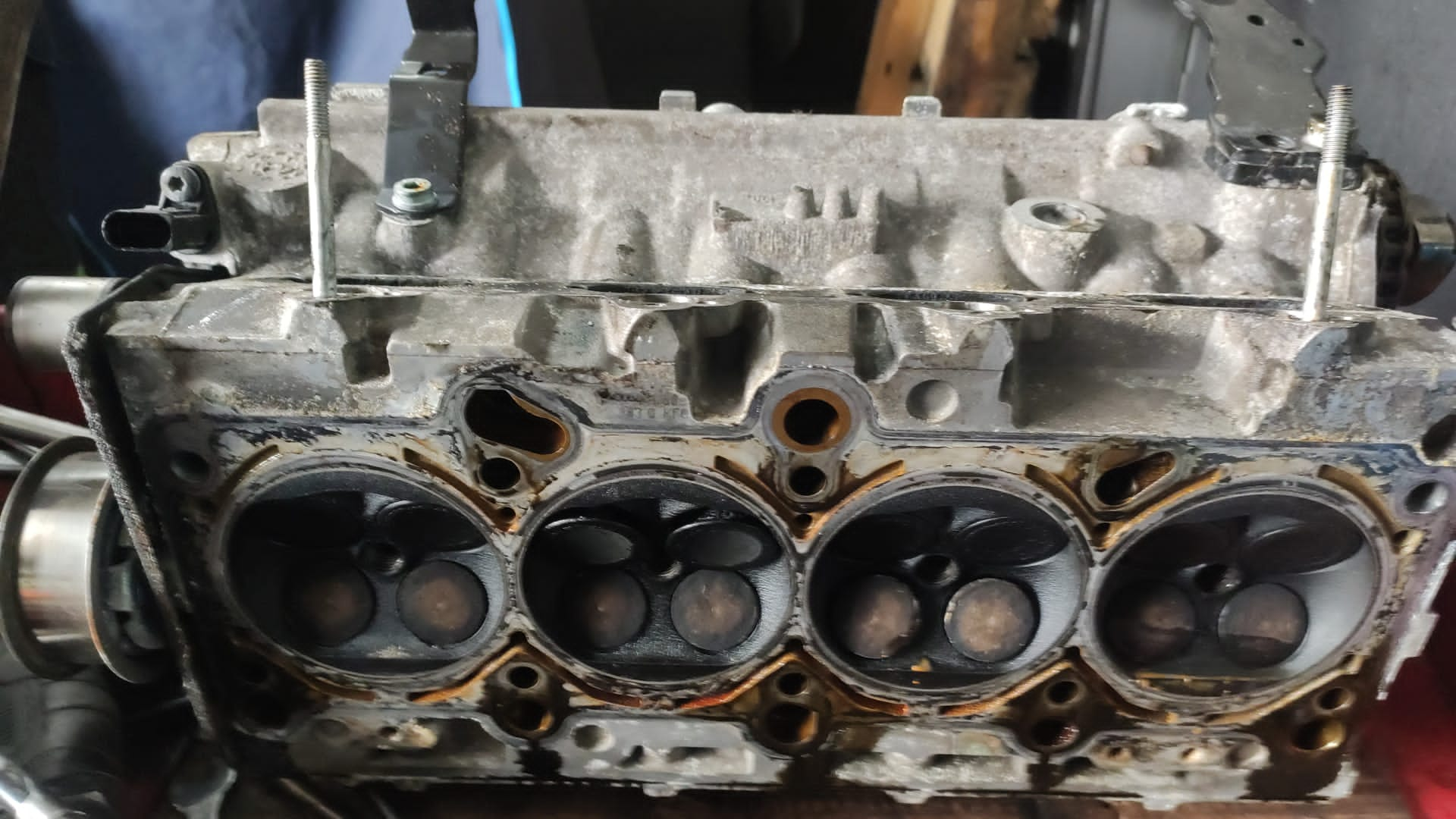

As we did not know the internal state of the engine and also the valves and the internal part of the cylinders had carbon (a very common problem in TFSI engines), we decided that it was best to check it thoroughly.

Marc (the mechanic) disassembled and reassemble it with all the guarantees and completely clean all internals as if the engine were knew.

Another thing that was done was to upgrade the clutch, and it was fitted with a DKM Stage 2 Uprated Clutch + Flywheel Kit for VW Golf V 2.0 GTI.

Positioning of the engine in the bay of the receiving vehicle#

At this point it is key to remember that the chassis of the receiving vehicle cannot be modified in any way, so after many hours of searching the internet I found Fabless Manufacturing.

At that time (this was in November 2021) they did not have the EA113 TFSI engine mounting kit in their catalogue, so I tried my luck and contacted them. My surprise was that they told me that they were developing it and that they could sell me one 😅

With the kit, and the body of the car restored and resprayed, Marc and I got down to put the engine. We needed 2 attempts and a few more emails to Fabless to clarify the assembly instructions.

First attempt#

In December 2022 we made the first attempt to fit the engine, but it was tilted to the right and uneven (and we had to support it with a chain and another support underneath). The kit’s anchor points are three; one in the middle at the front of the engine and two on each side at the rear of the engine (beware!…they are not the same mounts as on the Golf MK5 GTI).

And there was a trick. From Fabless Manufacturing they clarified that the subframe cups had to be moved. How? Very easy, as this video indicates. In fact, they have recently released the second part of the kit which is a tubular subframe where the cups are properly position to fit the engine. However, everything has a price and it’s not exactly cheap, but other than that my experience with Fabless Manufacturing has been great and they have always responded well and quickly. In addition, the quality of their products is unbeatable.

Second attempt and final#

After disassembling the subframe and making the modifications to the cups, we were able to try to fit the engine again. It was January 2023, and this time yes, the engine fit like a glove in the OEM position.

Intercooler and radiator#

One of the concerns we had was the performance of the radiator and fans from the original Golf MK3, so to be on the safe side we decided to put the following items:

- Mishimoto VR6 aluminum radiator

- 12" Spal fans of 1221 CFM each. In other words, more than enough for a 6 cylinder engine (see table at the following link) and the BWA has 4.

Another problem that popped up was which intercooler to use. There were 2 options in this case:

- Original intercooler. The dimensions of the core of this intercooler are about 615x405x32mm (7.9L and 129cm²). With this height, the intercooler would be very low (below the front spoiler of the Golf MK3) just a few centimeters from the ground, and would also require a significant modification of the engine crossbar. So it was discarded.

- Small size intercooler. We now know that the maximum height of the intercooler is limited to about 20cm by the engine crossbar. As a general rule (see the following link) the intercooler must have a volume of 3L and a section of 50cm² for every 100hp of the engine. In our case we are going to take the power of 200hp, and, therefore, the minimum volume and section are: 6L and 100cm². With these data, an intercooler with the following dimensions 550x180x65mm (6.5L and 117cm²) was chosen. To this we must add that the intercooler is made of high quality aluminum alloy.

Intake and exhaust lines#

As mentioned in the rules of the game section, here there is little room for maneuver if you want to make the vehicle road legal. These must be those of the donor vehicle.

The problem we had is that the final silencer of a Golf MK5 GTI does not fit on the chassis of the Golf MK3, so we had to contact several companies and ask whether they could make us an ECE approved exhaust for the Golf MK5 GTI (BWA) that could be mounted on a Golf MK3 chassis.

Additional features#

The extras that can be added to the BWA engine of the Golf MK5 are those shown below. These extras are not eligible for approval and, therefore, are here for informational purposes.

This configuration with the correctly programmed ECU allows for outrageous power figures (>350hp) to be obtained from the engine, but in return, engine reliability is also sacrificed. More information about this setup can be found in this video.

- Golf MK5 GTI ED30 injectors (06F 906 036 F).

- Turbocharger (K04) from the Golf MK5 GTI ED30 (06F 145 702 C).

- Audi RS4 FRPV (FuelRail Pressure Valve) 136 bar (079 130 757).

- Fuel Rail Pressure Sensor 200 bar (06J 906 051 D)

- MAP Sensor 3 bar (038 906 051 C)

- Improvement or upgrade of HPFP – VIS Motorsport - 2.0 TFSI EA113 HPFP Upgrade Kit.